環境

豊かな地球環境の持続に向けて

概要

基本的な考え方

近年、ESG、SDGs、カーボンニュートラルなどの気運の高まりとともに、地球規模での気候変動への取り組みがかつてないほどの高水準で企業に求められています。ニチレキグループは、脱炭素社会・循環型社会の実現、生物多様性の保全といった環境課題の解決と、事業の持続的な発展を高いレベルで両立させることを目指しています。そのために環境経営委員会を設置し、気候変動を含む環境課題全般に関するニチレキグループの取り組みとその評価・見直しなどを審議・検討するとともに、サステナビリティの視点で環境対策の管理徹底を図っています。

環境に関する方針と体制

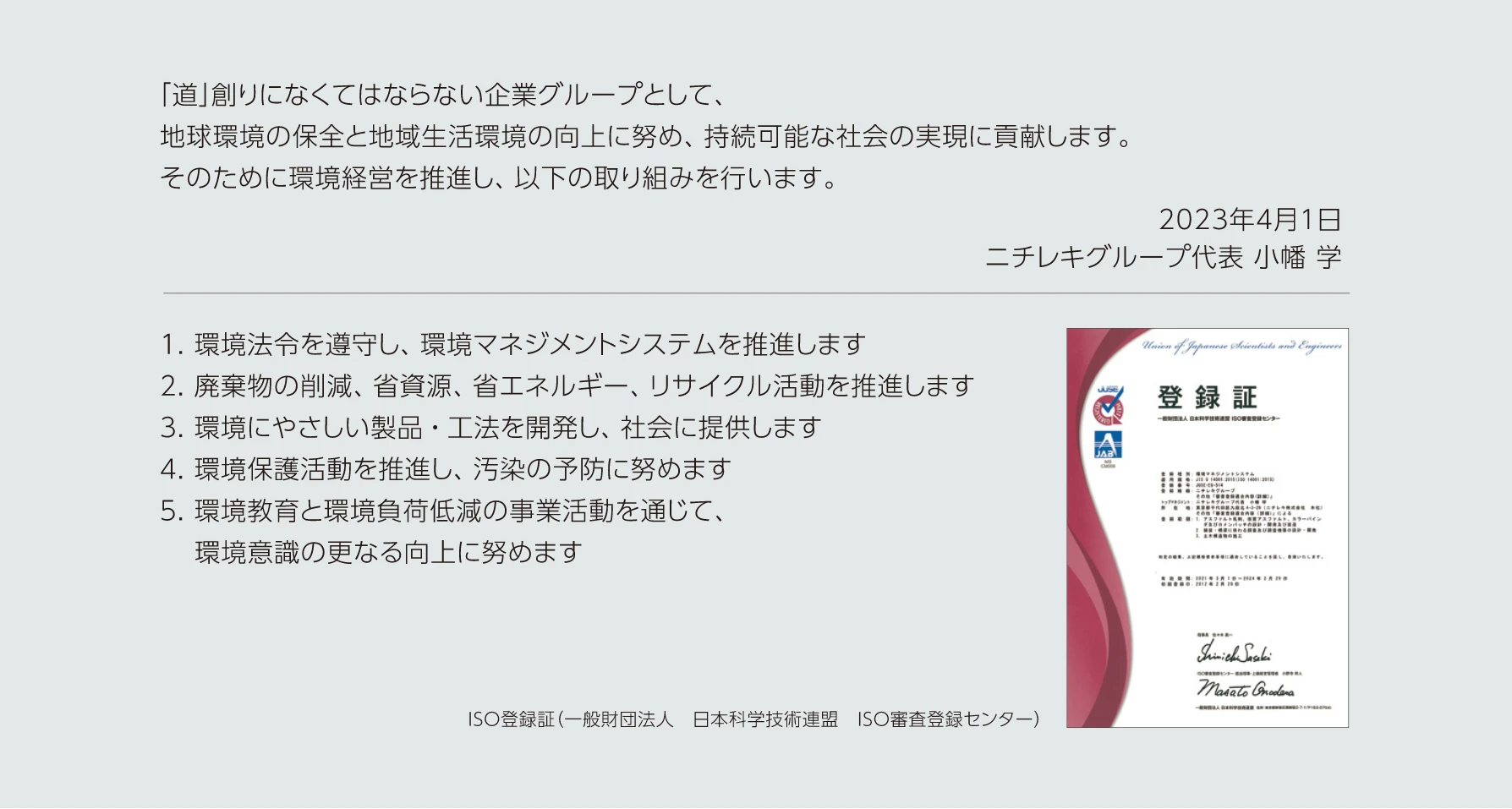

2012年2月、ニチレキグループは従来から取り組んできた品質マネジメントシステム(ISO9001)に加え、環境マネジメントシステム(ISO14001)を含めたマネジメントシステム統合による認証を取得しました。環境マネジメントシステムの根幹となる「環境方針」には、5つの具体的な取り組みが示されており、法令遵守はもちろんのこと、廃棄物削減、省資源・省エネルギー、リサイクルなど、環境に優しい製品・工法の開発と提供を推進しています。

環境方針

環境マネジメントシステム体制図

脱炭素社会・循環型社会の実現

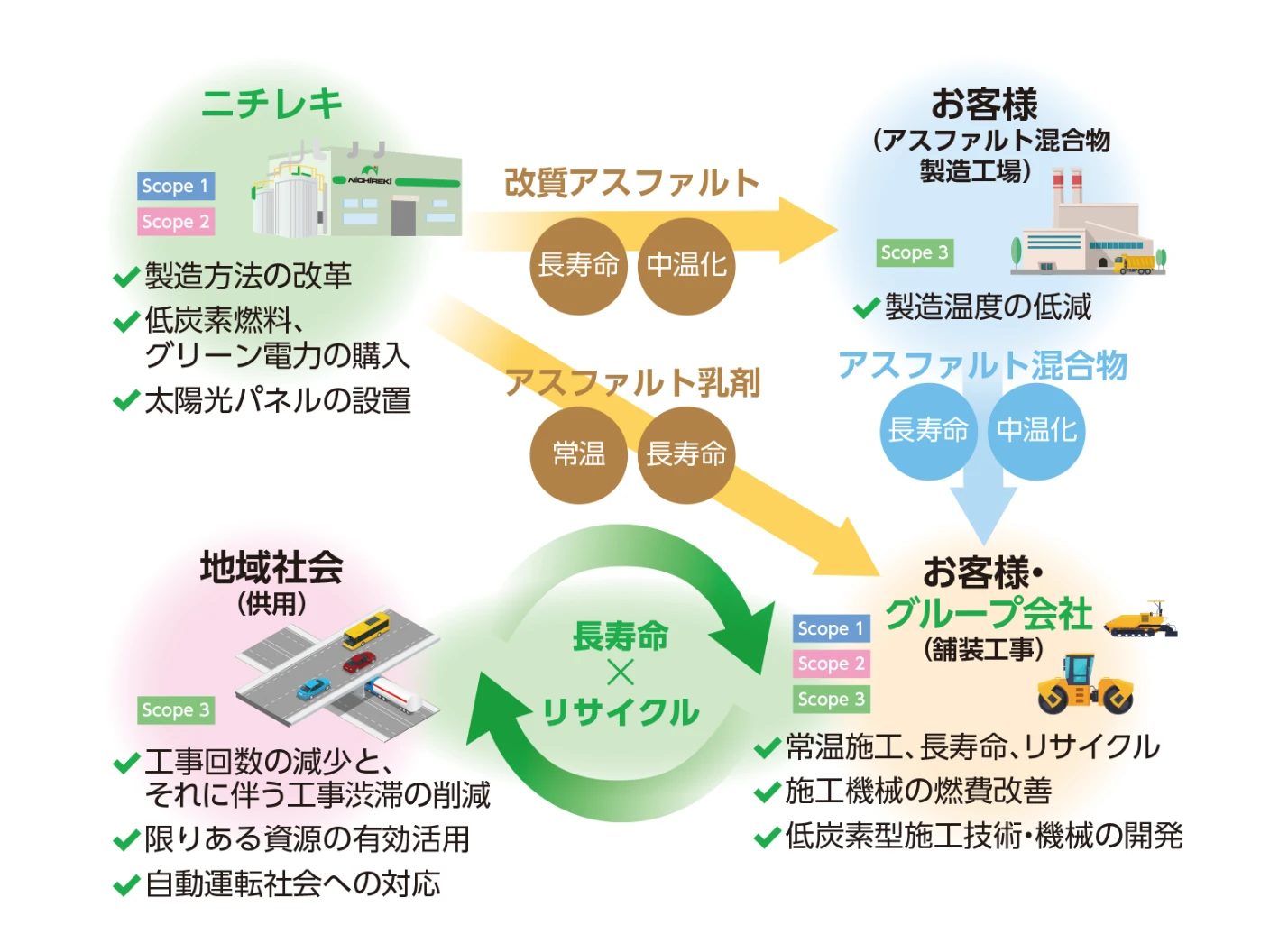

ニチレキグループは、アスファルト乳剤による常温舗装や、中温化改質アスファルトによる混合物の製造温度の低減に加え、舗装の長寿命化やリサイクルに資する製品・工法の開発・提供等を通じ、CO2排出量の削減に取り組み、脱炭素社会の実現に貢献しています。さらには、事業所内におけるゴミ分別の徹底による資源再利用化の促進や、電力のグリーン化にも取り組んでいます。2050年のカーボンニュートラル(CO2をはじめとする温室効果ガスの排出量の実質ゼロ化)実現に向け、今後も取り組みを一層加速していきます。

生物多様性の保全

生物多様性の保全に資する取り組みの一つに森林の間伐があります。密生した森林を適切な間隔で伐採することで、太陽光が木々に十分に差し込み健全な森林が形成され、そこに暮らす様々な生物たちの棲みかが守られます。間伐発生材は様々な用途で利用されていますが、利用しきれずに焼却処分されるケースもあります。ニチレキではそうした間伐材を細かく破砕してアスファルト乳剤と混合し、「アスウッド舗装」として公園の遊歩道などの舗装に適用することで、間伐材の利用促進につなげています。さらには事業所を構える各地域における道路や河川の清掃・緑化活動等にも積極的に参加するなど、地域貢献活動の面からも、生態系の保護に貢献しています。

アスウッド舗装

気候変動への対応

TCFD提言に基づく開示

ニチレキグループでは、気候変動による事業への影響を重要な経営課題の一つと捉え、「気候関連財務情報開示タスクフォース(以下、TCFD)」に賛同し、気候変動対策に積極的に取り組んでいます。

気候変動がもたらすリスクと機会における事業インパクトを明確化し、対応策を講じることで、事業の継続性強化を図るとともに、社会の持続性と企業価値の向上につなげていきます。

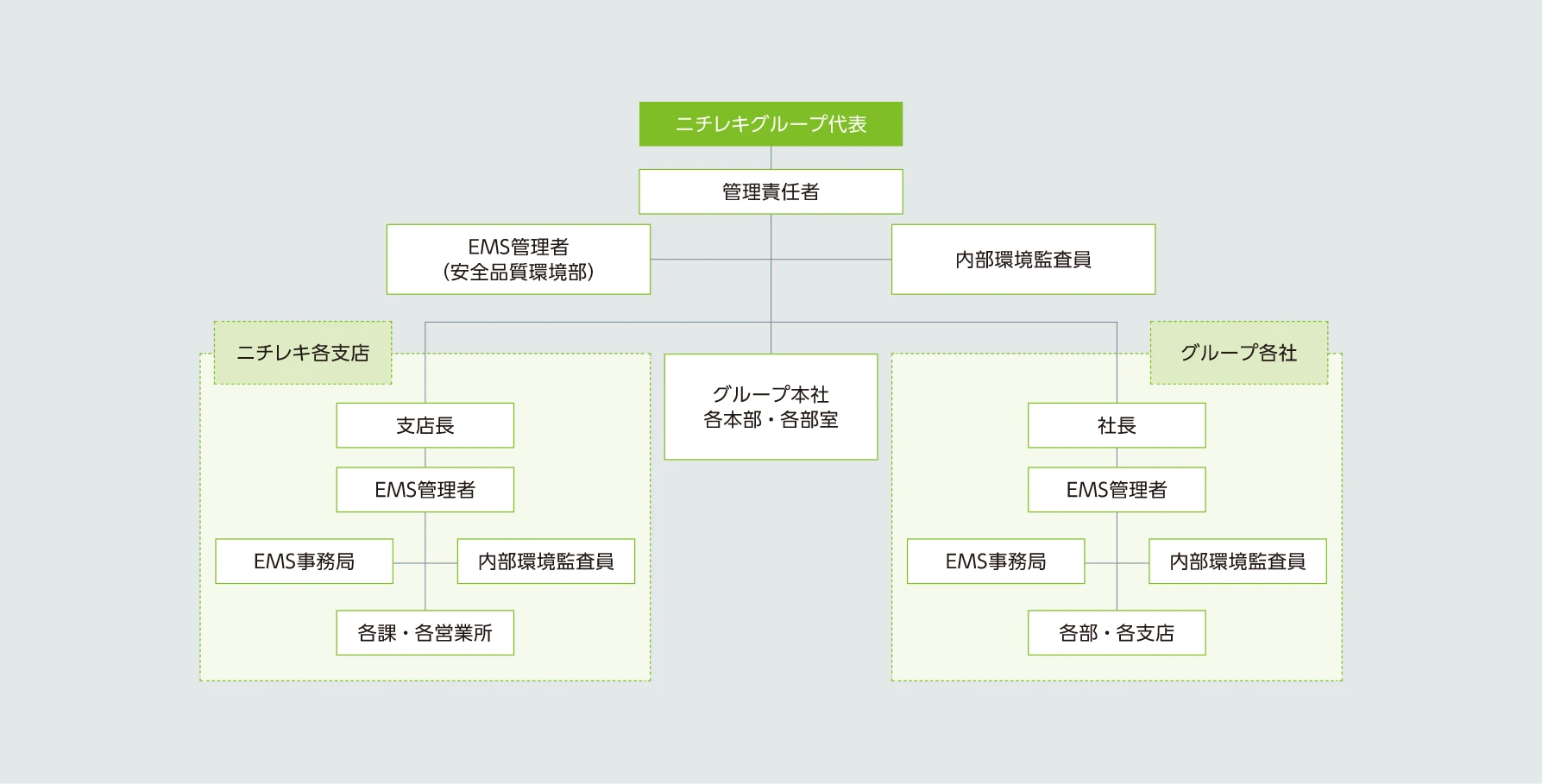

ガバナンス

ニチレキグループでは、気候変動問題を含む環境問題全般についての基本方針等の重要事項は取締役会で審議の上、決議されることとしています。特に、グループ横断的な環境問題への対応につきましては、代表取締役社長を委員長とし、企画・管理・事業・技術開発の各本部長を委員とする「環境経営委員会」で審議・検討され、最終的に取締役会に上程される体制としています。環境経営の進捗状況や環境課題に係る事業のリスクと成長機会は、毎年取締役会に報告、レビューされます。

リスク管理

ニチレキグループでは、上記「環境経営委員会」において、定期的に気候変動関連のリスクのモニタリングを行い、グループ横断的なリスクマネジメントを行う体制としています。また、テールリスク(発生確率は低いものの、発生すると非常に大きな損失を被ることになるリスク)にも十分対応できるよう、今後、シナリオ分析と評価を充実させるなど、当社の経営に重大な影響を与える可能性のある重要リスクを適切に抽出し検討する手法の高度化に取り組んでいきます。

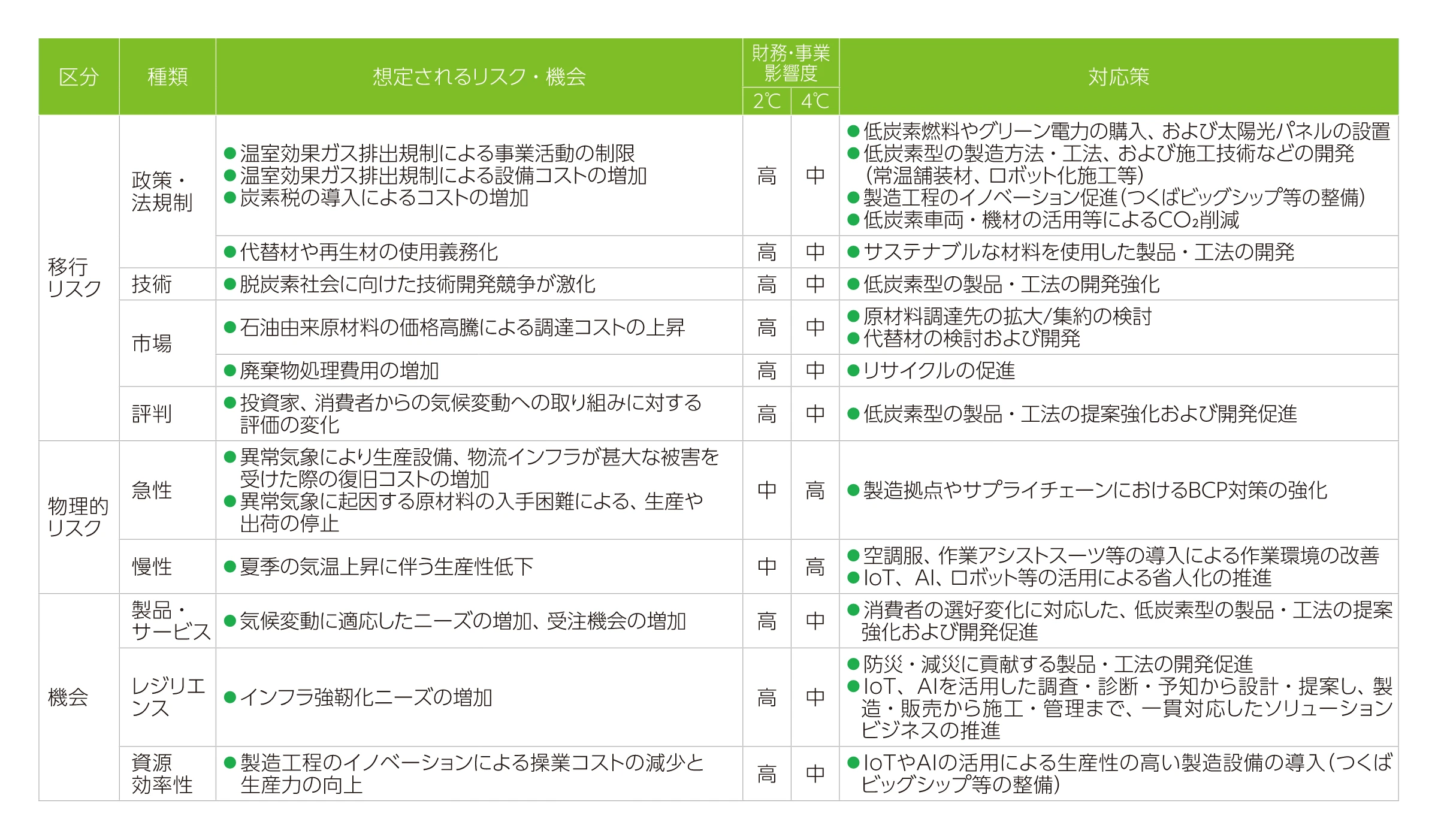

戦略

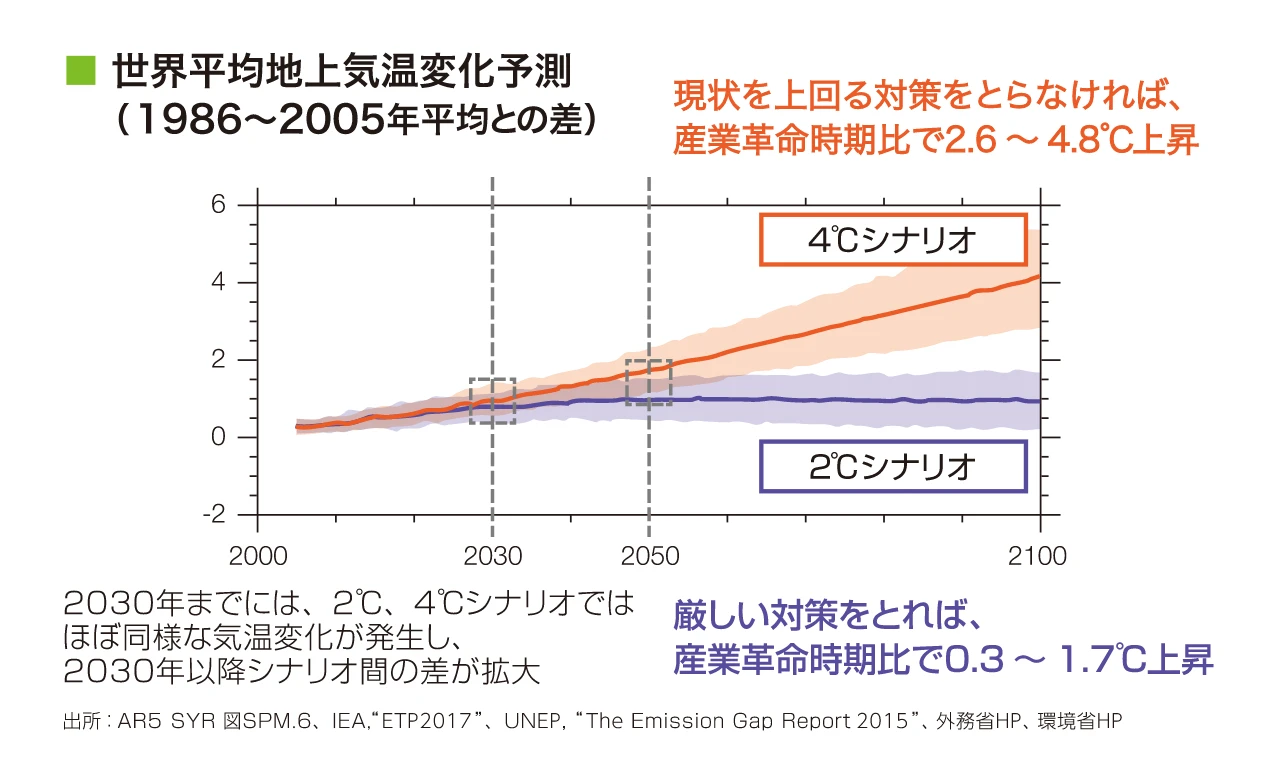

ニチレキグループでは、短期および中長期の双方の視点で、気候変動関連のリスクと機会を特定するとともに、パリ協定の目標が達成されることを前提としたシナリオ(いわゆる2℃シナリオ)と、追加的な政策対応がないシナリオ(いわゆる4℃シナリオ)でのシナリオ分析を行い、事業への影響度の評価と、その対策についての検討を実施しています。今後、対応策のレジリエンスを継続的に評価し、必要に応じて新たな対応策の検討を行っていきます。

2℃未満シナリオ

脱炭素に向けた規制や政策が強化され、気候変動への対策が進捗し、産業革命前の水準からの気温上昇が2℃未満程度に抑えられるシナリオ。

4℃シナリオ

追加的な規制や政策の導入がなく、気候変動対策が十分になされず、産業革命前の水準からの気温上昇が4℃程度となるシナリオ。

シナリオに基づくニチレキグループにおけるリスクと機会の想定、財務・事業影響度評価、および対応策

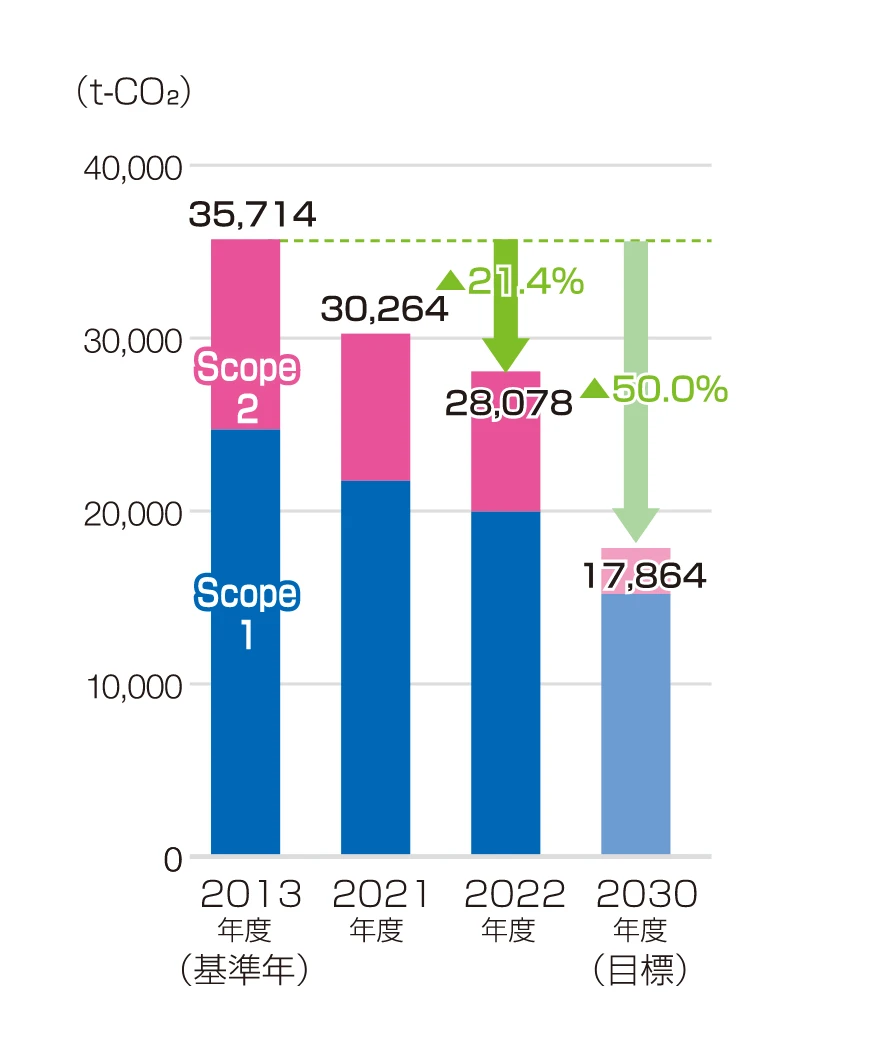

指標と目標

ニチレキグループは、「2050年までにバリューチェーン全体の温室効果ガス排出量ネットゼロ」を長期目標に設定しました。また、政府が決定した「2030年に、温室効果ガスを2013年度から46%削減することを目指す」との目標を十分踏まえ、「2030年度までに、温室効果ガス排出量を2013年度からScope1+2*で50%削減」を中期的 な目標として設定しました。今後、この目標水準の達成に向け、製造方法等の改革、グリーン電力の購入や太陽光パネルの設置を促進するとともに、中長期的には、低炭素燃料・脱炭素燃料や、水素・電気を利用した自動車・建設機材も積極的に活用していきます。また、長寿命化・中温化舗装用改質アスファルト等の環境配慮型製品の販売拡大、さらには低炭素型の常温舗装材料および施工技術の開発促進にも取り組んでいきます。なおScope3については、今後カテゴリ別のCO2排出量の把握を進め、Scope1、2と併せて具体的な削減施策の検討を進めてまいります。

- :事業者自らによる温室効果ガスの直接排出

(燃料の燃焼、工業プロセス) - :他社から供給された電気、

熱・蒸気の使用に伴う間接排出 - :Scope1、Scope2以外の間接排出

(事業者の活動に関連する他社の排出)

CO2排出量

CO2削減イメージ

環境に配慮した製品・工法

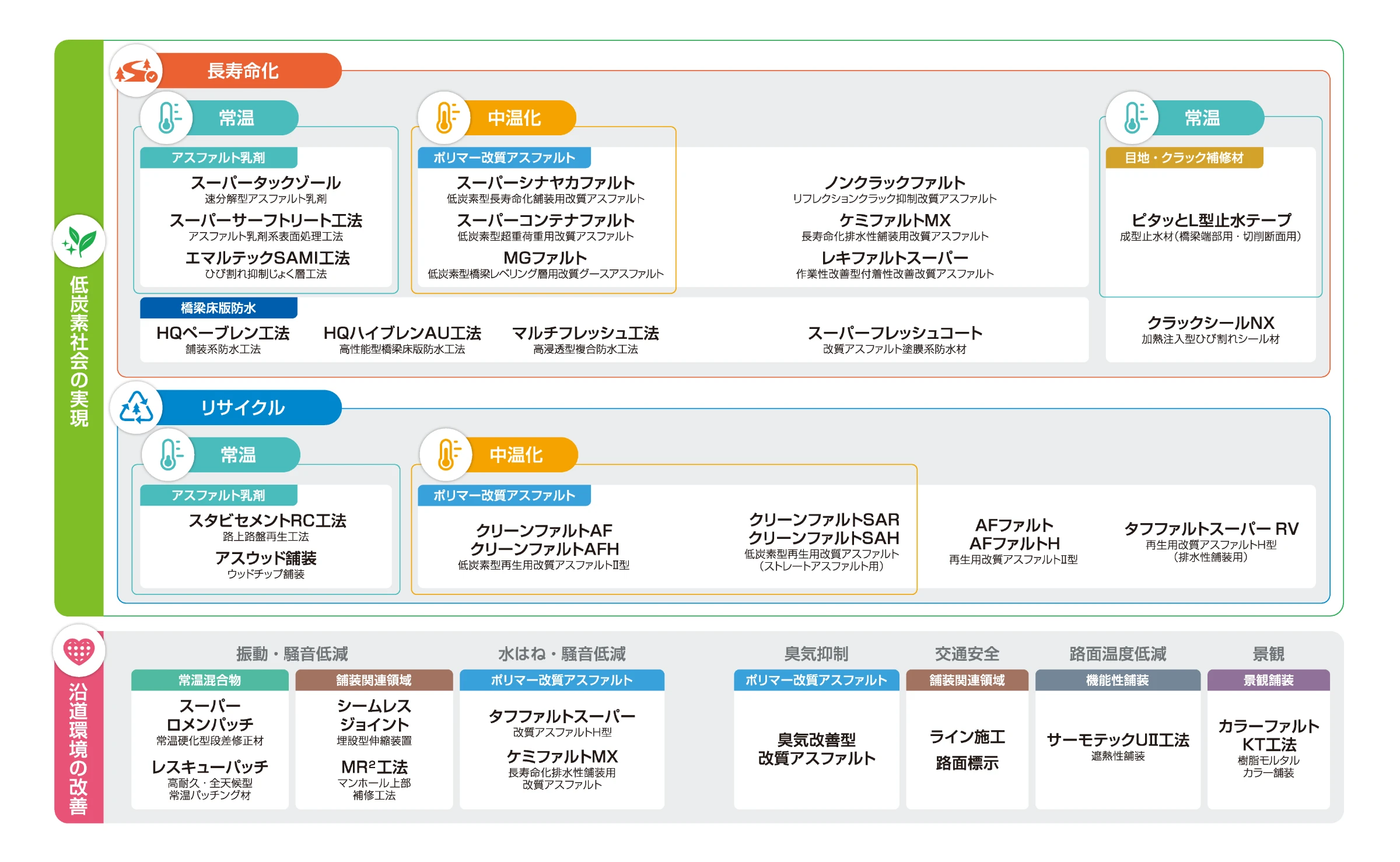

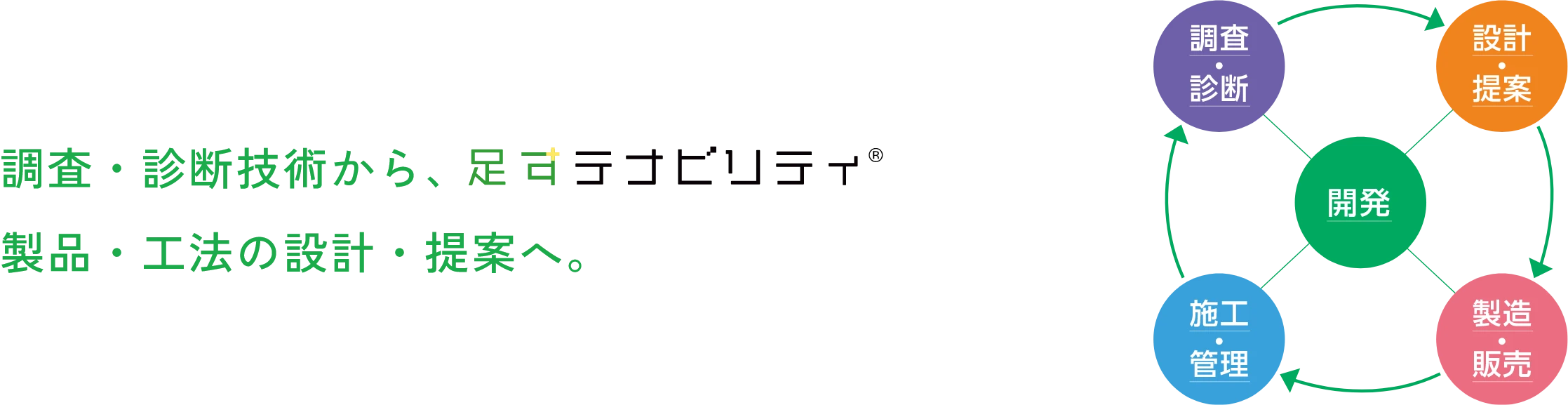

ニチレキグループは、お客様をはじめとするステークホルダーの皆様のCO2排出量削減ニーズにお応えします。これまでも、アスファルト乳剤など常温で扱える製品・工法により、環境に配慮した「道」創りに取り組んできました。それに加え、新たに長寿命、リサイクルなどの性能・機能をプラスする「足すテナビリティ®」製品・工法の提供を通じ、さらなるCO2排出量の削減ニーズに応えていきます。また、振動・騒音の低減や交通安全、路面温度の低減など、沿道環境の改善にも併せて取り組んでいくことで、持続可能な「道」創りに貢献します。ニチレキの代表的な環境配慮型製品・工法群を下図に示します。

低炭素社会の実現

長寿命化

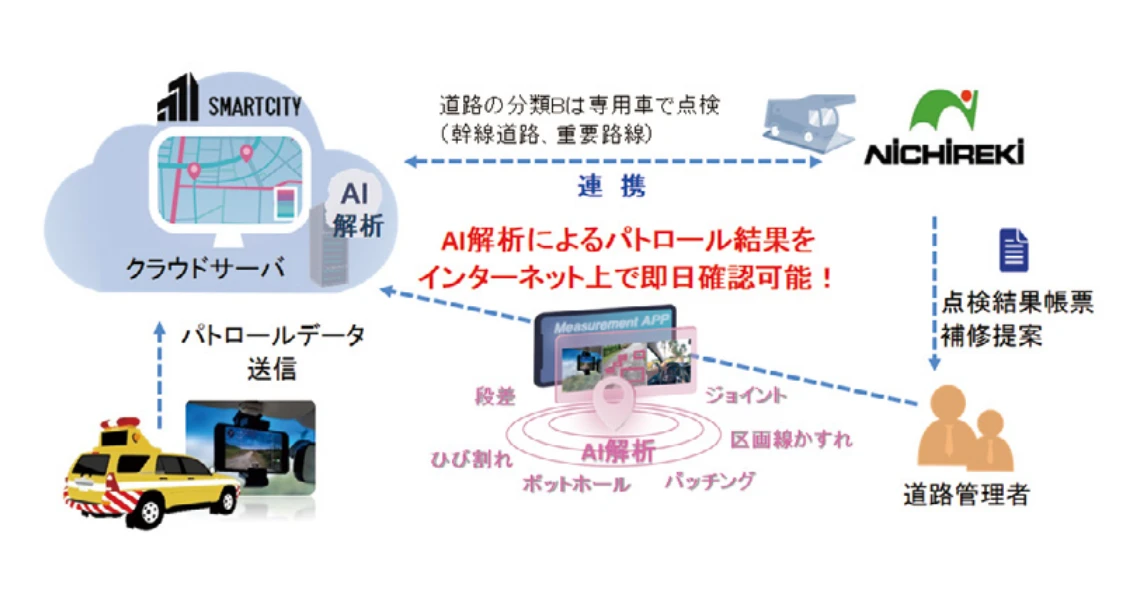

GLOCAL-EYEZ

一般車両に取り付けたスマートフォンで舗装道路を撮影するだけで、路面のひび割れやわだち掘れなどを「いつでも、どこでも」点検することができます。これにより、日々の道路管理から修繕工事区間の選定までを支援することができます。

点検~解析のイメージ

点検結果の活用イメージ

smartロメンキャッチャーFWD

修繕工事が必要であると選定された箇所の路面に衝撃荷重を与え、その時に生じるたわみ量を計測します。これにより、舗装内部の健全度を非破壊で診断し、どの層が傷んでいるかを特定することで、損傷状態に応じた適切な修繕方法を提案できます。

smartロメンキャッチャーFWD

たわみ量計測の様子

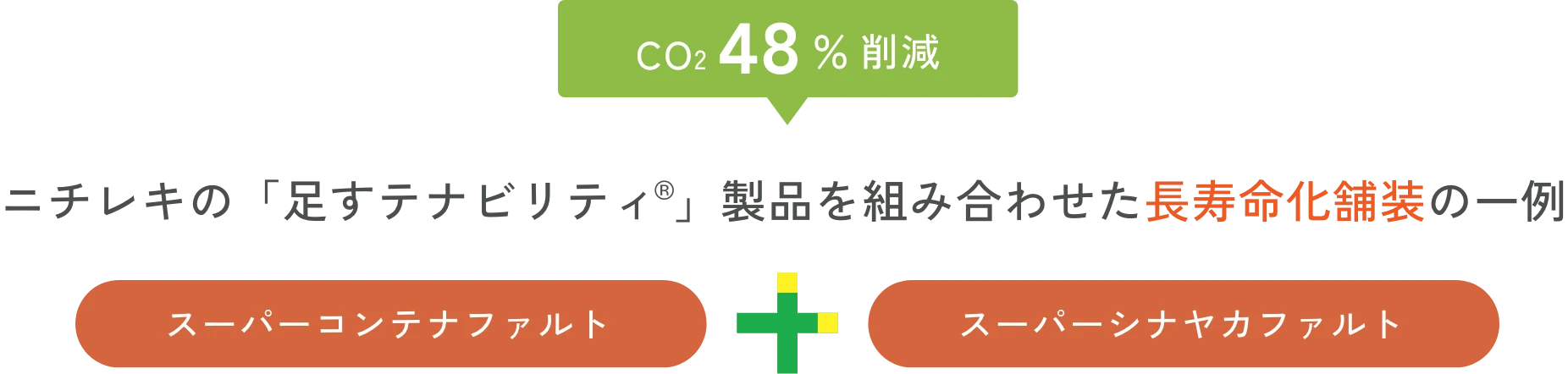

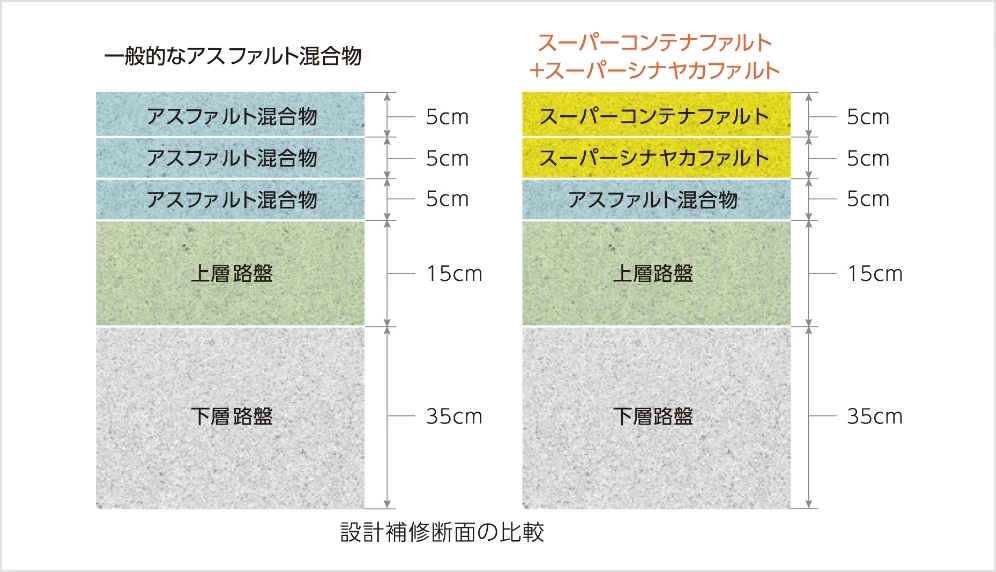

長寿命なアスファルト混合物である、スーパーコンテナファルトとスーパーシナヤカファルトを組み合わせて舗装することにより、これまでにない長寿命化舗装を実現できます。これにより、50年間の舗装のライフサイクルにおいて、CO2排出量を約48%削減できます。

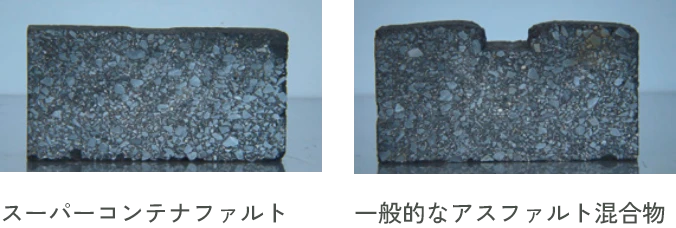

スーパーコンテナファルト

極めて高い塑性変形抵抗性を有する超重交通用改質アスファルトです。

港湾・空港などの重荷重車両が走行する箇所でも高い耐久性を発揮し、舗装の長寿命化に貢献します。

従来品である「コンテナファルトS」に比べ、混合物の製造温度を185℃から155℃に30℃低減し、混合物製造時の燃料消費量を抑制できることから、CO2排出量を約13%削減できます。

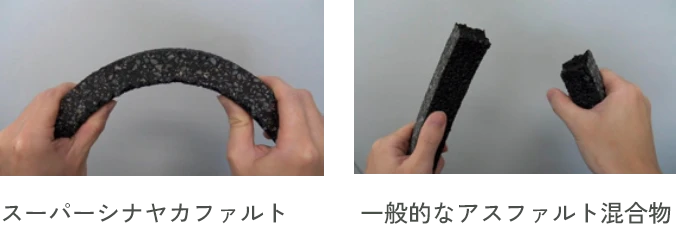

スーパーシナヤカファルト

手で曲げられるほどの柔軟性と、交通荷重に耐えうる強靭性を兼備した特殊改質アスファルトです。

一般的なアスファルト混合物に比べて1.7倍の性能付与により、舗装の長寿命化に貢献します。

従来品である「シナヤカファルト」に比べ、混合物の製造温度を180℃から130℃に50℃低減し、混合物製造時の燃料消費量を抑制できることから、CO2排出量を約22%削減できます。

長寿命化(橋梁)

smart床版キャッチャー

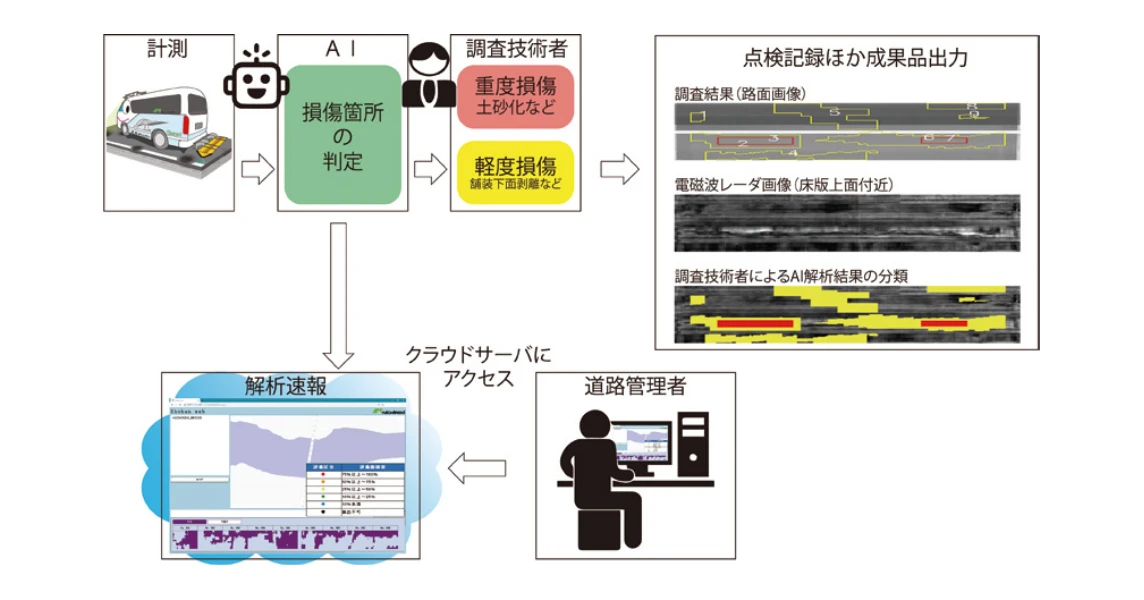

電磁波技術を活用し、アスファルト舗装を剥がすことなく、橋梁コンクリート床版上面の損傷状況を調査することができます。AI解析により、損傷度合いを素早く判定することが可能です。損傷状況に応じて、開削調査と組み合わせることで、精度の高い修繕設計が可能となります。

smart床版キャッチャー

点検~解析のイメージ

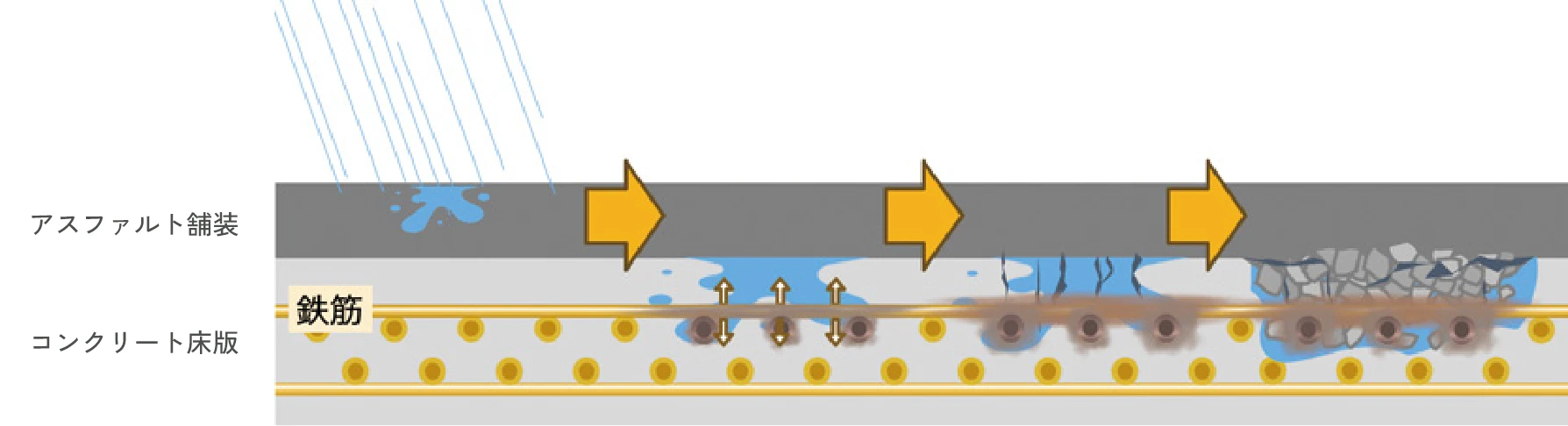

橋梁床版の劣化進行イメージ

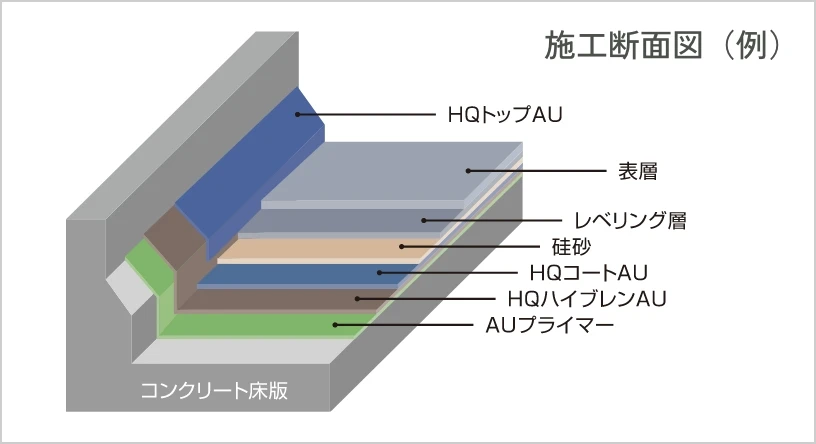

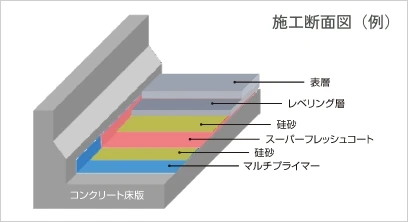

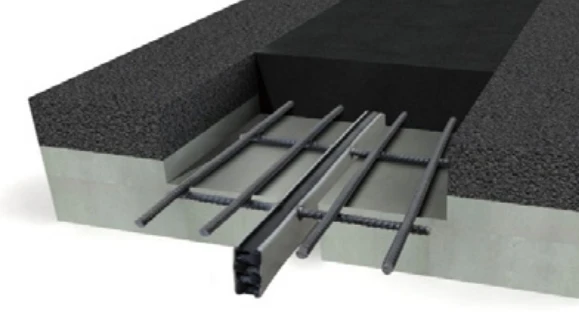

橋梁の舗装を支える「コンクリート床版」に水が染み込むと、内部の鉄筋が腐食・膨張し、床版にクラックが発生します。これが発展すると、砂利化等の重大な損傷につながるため、耐久性の高い橋梁床版防水層の構築が必要となります。ニチレキはそれぞれの現場の状況・条件に合わせて、適切な高耐久型橋梁床版防水工法を提案します。

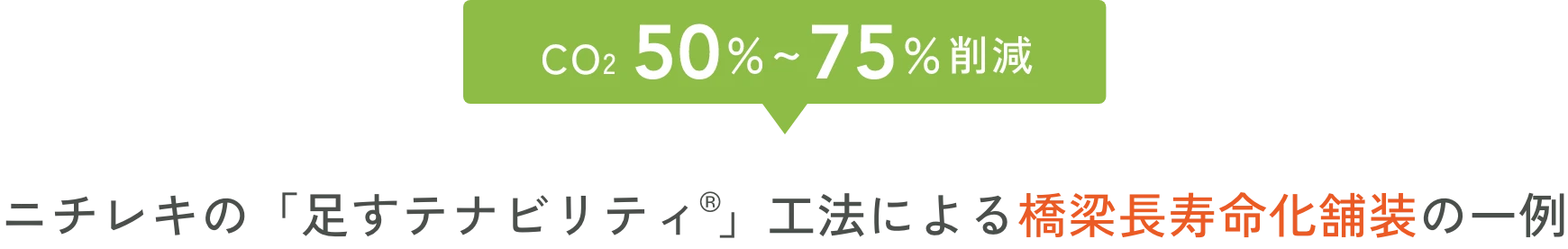

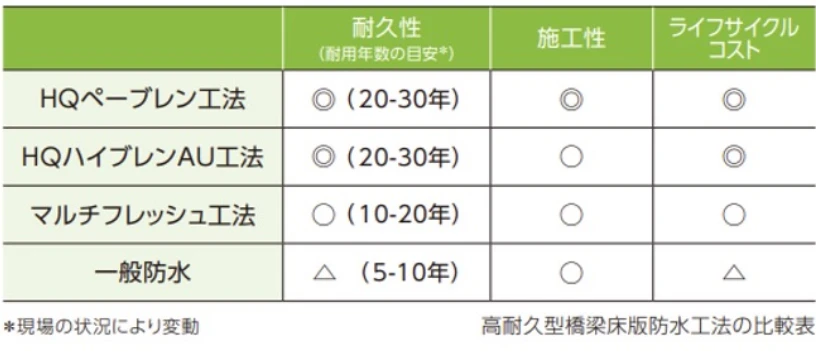

高耐久型橋梁床版防水工法

橋梁は、人や交通、経済をつなぐ重要なライフラインであるため、日常を途切れさせないように長持ちさせなければなりません。また、長持ちさせることで補修頻度を低くできることから、50年間の舗装のライフサイクルにおいて、CO2排出量を約50%〜75%削減できます。ニチレキが提案する高耐久型橋梁床版防水工法は以下の通りです。

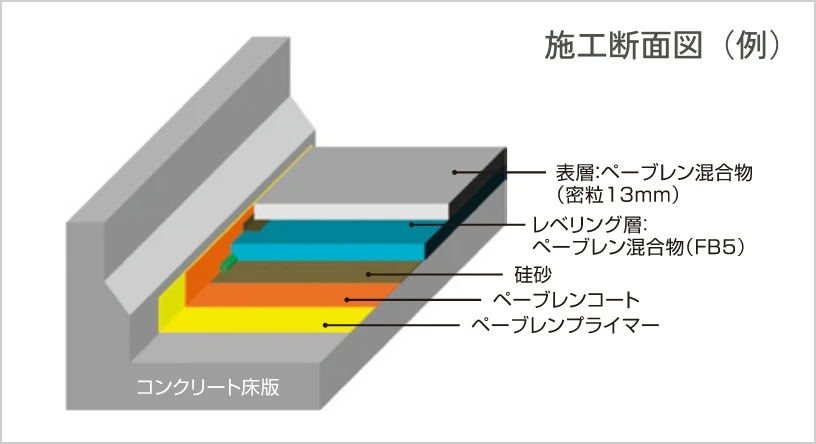

HQペーブレン工法

30年相当のひび割れ開閉負荷試験に合格し、せん断疲労抵抗性に優れた工法です。高性能な舗装系防水であるため、凍結抑制剤や飛来塩分からも床版を守り、長寿命化に貢献します。

HQハイブレンAU工法

供用30年相当の負荷を与えた性能規格に合格する、アスファルトとウレタンを融合させた、耐久性の高い塗膜系床版防水工法です。

マルチフレッシュ工法

コンクリート床版上面のひび割れに浸透するプライマーと、高耐久なアスファルト加熱塗膜系防水材を塗布する複合防水工法です。床版の剛性と疲労抵抗性の向上が期待でき、長寿命化に貢献します。

なお、HQハイブレンAU工法やマルチフレッシュ工法を選定した場合、防水層の上に長寿命なアスファルト混合物(レキファルトスーパー)を舗装することにより、さらなる長寿命化が期待できます。

レキファルトスーパー

剥離抵抗性や施工性に優れたポリマー改質アスファルトです。施工時期にとらわれず高い締固め度の混合物が得られるため、舗装の長寿命化につながります。

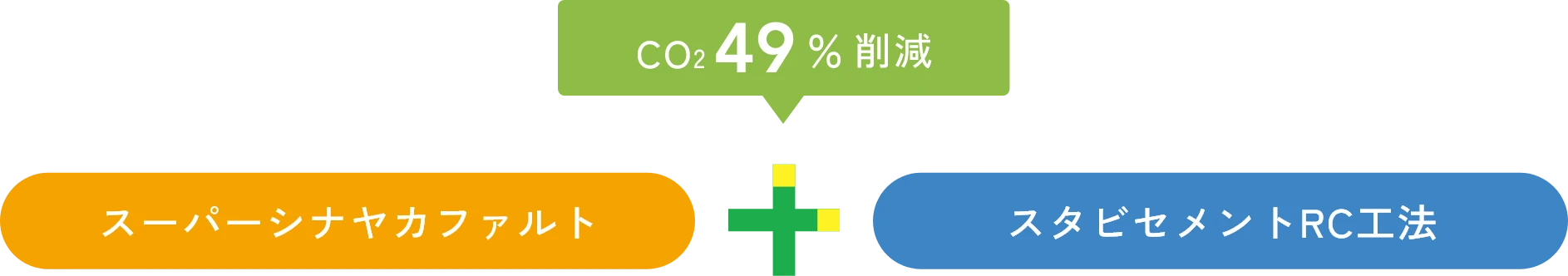

破損が進行した既設舗装を現位置で再利用して構築した(スタビセメントRC工法)基盤の上に、長寿命なアスファルト混合物(スーパーシナヤカファルト)を舗装することにより、これまでにない長寿命化舗装を実現できます。

これにより、50年間の舗装のライフサイクルにおいて、CO2排出量を約49%削減できます。

スーパーシナヤカファルト

手で曲げられるほどの柔軟性と、交通荷重に耐えうる強靭性を兼備した特殊改質アスファルトです。

スタビセメントRC工法

破損が進行した既設舗装を現位置で破砕し、同時にアスファルト乳剤(常温)およびセメントを混合し、新たな舗装を構築します。

破損が進行した既設舗装

ロードスタビライザによる施工状況

既設舗装の大部分をそのまま現場で利用するので、材料の搬出・搬入が少なく、省エネルギー、資源の有効活用、およびCO2排出量の削減に貢献します。特に、1回の工事につき現場から排出する舗装廃材は約80%削減できます。

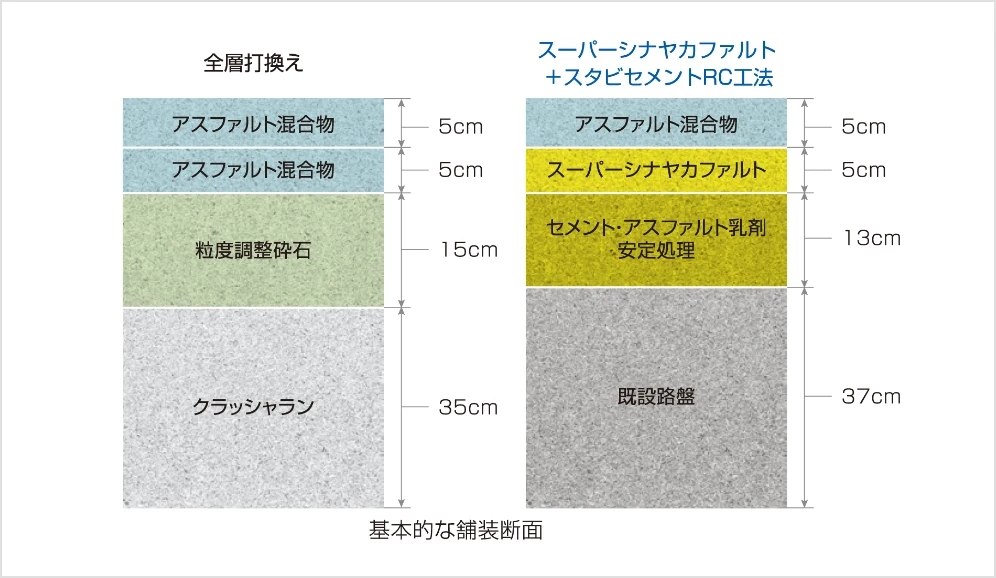

スタビセメントRC工法にi-construction(建設現場にICTを活用する取り組み)を導入しました。これにより、遠隔地からでも施工データをリアルタイムで確認でき、建設現場の生産性向上に貢献します。また、施工精度を高めてより品質の高い路盤を構築できるので、舗装の長寿命化にもつながります。

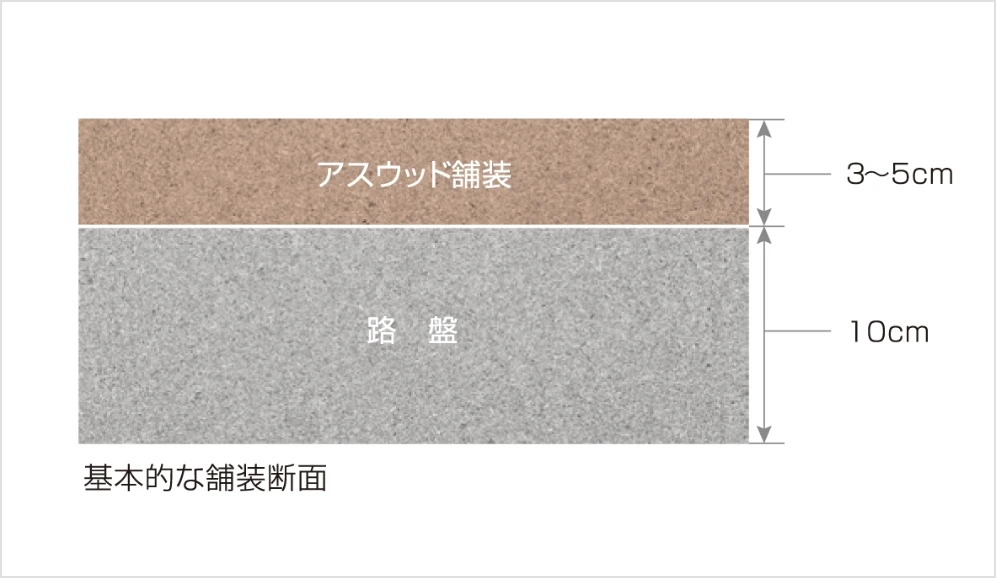

アスウッド舗装

たわみ性に優れたゴムアスファルト乳剤「アスウッド乳剤」と木材チップを用いた木質系(ウッドチップ)舗装です。混合物の製造から施工までを常温で行えるため、環境に優しく、通常の加熱舗装と比べてCO2排出量を約34%削減できます。

間伐材等を燃やさずに利用することは、CO2を大気中に戻さずにそのまま閉じ込めること(固定化)にもなります。例えば、厚さ4cmで1,000㎡をアスウッド舗装で施工した場合、杉の木約1,300本が年間に吸収する量(約18t)に相当するCO2を固定化することができます。また、松くい虫やナラ枯れなどの被害木や、放置竹林の竹の利活用も可能です。

運搬可能な自走式木材粉砕機

クッション性と透水性に優れ、歩く人やジョギングする人の足に優しく、水たまりができにくいことに加え、周囲の自然に溶け込む優しい風合いが人々に癒しをもたらします。

アスウッド舗装

ニチレキは、木の利用を通じて持続可能な社会へチェンジする、

林野庁の「ウッド・チェンジ」の趣旨に賛同し、木材利用の取り組みを積極的に推進しています。

沿道環境の改善

振動・騒音などの低減で、

製品・工法にも、環境への配慮を。

スーパーロメンパッチ

振動・騒音低減

道路の段差を補修する、摩耗抵抗性に優れた常温硬化型のアスファルト乳剤混合物です。

常温で施工できるため、環境に優しい材料です。

施工には機械を使わないので容易に作業できます。

スーパーロメンパッチ

施工後の状況

レスキューパッチ

振動・騒音低減

道路の穴ぼこを補修する、耐久性に優れた常温混合物(パッチング材)です。

常温で施工できるため、環境に優しい材料です。

降雨や降雪などにより、施工面が濡れていても施工可能です。

レスキューパッチ

施工後の状況

ケミファルトMX

水はね/騒音低減

雨天時、舗装路面に滞水しにくい排水性舗装です。走行時のすべり、水はね、視認性の悪化を防ぐことで、交通事故の減少につながります。

また、走行による路面からの騒音を低減することもできます。

骨材飛散抵抗性に優れ、高い耐久性を発揮することから、舗装の長寿命化にも貢献します。

一般的な舗装

排水性舗装

MR2工法

振動・騒音低減

マンホールと舗装の段差補修を低振動・低騒音で施工できる工法です。材料の硬化が早く、短時間で施工ができます。

常温混合物でマンホール周りを施工するので環境に優しく、また、温度低下などの影響による締固め不足が生じず、長寿命化にも寄与します。

施工状況(マンホールの撤去)

施工後の状況

シームレスジョイント

振動・騒音低減

橋のジョイントを埋め込む、埋設型の伸縮装置です。路面に鋼材やゴムが露出しないため、車両がスムーズに走行できます。

止水性能と品質安定性に優れ、長期にわたり使用できるため、橋梁の長寿命化にも寄与します。

シームレスジョイント

施工後の状況

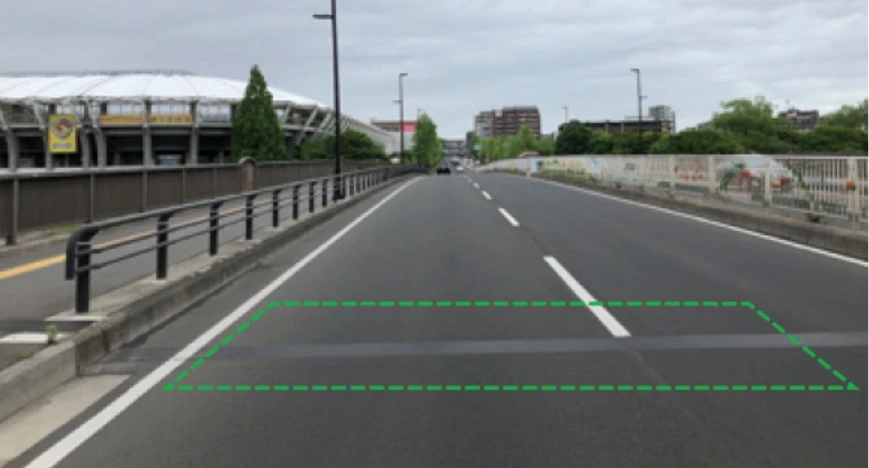

路面標示

交通安全

立体的に見える路面標示やカラー舗装などにより、ドライバーに視覚的に注意を促し、速度の抑制や誤侵入の防止等を通じて、

交通安全に寄与します。

立体的に見える路面標示

首都高速道路のETC専用レーン表示