Details of Each Business and Business Processes

Research and development of eco-friendly products and construction methods

To further enhance the quality and accuracy of our development activities, in recent years we have assigned around 10% of Nichireki employees to our Technical Research Center, which forms the heart of our R&D activities. We are also investing more than 10% of our consolidated operating profit in R&D. We have installed new performance evaluation testing machines in addition to our conventional testing equipment to promote R&D to align with the era of social infrastructure maintenance, such as service life extension and large-scale renovation of roads. The Technical Research Center also serves as a comprehensive R&D institution that contributes to developing the capabilities of employees through the provision of training.

Survey and diagnosis to support road infrastructure management

Nichireki has also been working on the digital transformation (DX) of road inspections by leveraging ICT, IoT, and AI technology. For instance, we have developed SMART ROMEN CATCHER LY Jr. (road surface condition measuring vehicles), which inspects the damage of road paving; SMART ROMEN CATCHER FWD (pavement deflection amount measuring vehicle), which diagnoses the structural soundness of the road pavement; and SMART SHOBAN CATCHER (non-destructive bridge deck survey vehicle), which identifies the range and depth of damage locations on the top surfaces of concrete deck inside bridges. Furthermore, we offer GLOCAL-EYEZ (smartphone-based road inspection system), which allows anyone with a smartphone and a vehicle to inspect roads at low cost.

Safe and high-quality construction and management utilizing ICT and robotic construction machinery

By promoting the digitalization and robotizing processes to ensure reliable construction and management, we seek not only to earn the trust of the customers who entrust us with construction work, etc., but also to make residents living along roads feel safe. To give an example, with the STABI-CEMENT RC construction method (on-site base course recycling construction method), which allows damaged pavement to be reused and transformed into new pavement at the current location, we have worked to improve productivity and precision in construction and quality control by utilizing the ICT that measures various data in real time.

Design and proposal for optimal maintenance & management plans and repair methods

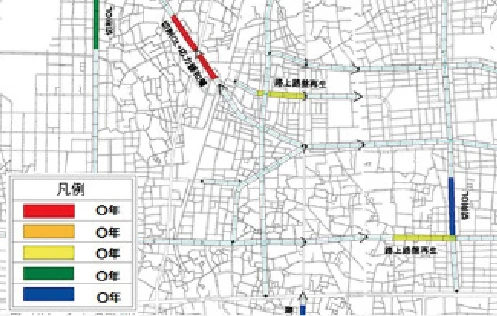

We assist in creating a pavement maintenance cycle to make road infrastructure last longer and help people have a safe and comfortable living environment. For medium- to long-term pavement maintenance and management planning, we calculate lifecycle costs using various combinations of repair methods, and then select the most economical pattern of methods from a preventive maintenance perspective. And based on this, we draw up repair plans for each fiscal year, and propose the optimal repair methods.

Illustration of breakdown maintenance and preventive maintenance cycles

Manufacture and sale of high value-added products that offer superior environmental performance

Our eco-friendly plants manufacture high value-added products that help customers address their various challenges, such as CO2 emission reduction, service life extension, and recycling. We have also implemented a logistics management system powered by ICT to create a sales system while staying mindful of convenience for customers.