Methods

Click here for more information about the PRMS Construction Method Council Overview>>

Overview

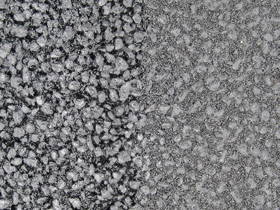

The PRMS construction method is a resin-based mortar construction method that fills the voids in the surface of porous asphalt paving with water-permeable resin mortar. This strengthens the surface of the porous asphalt paving, allowing maintenance of the function and extension of the paving lifetime.

The PRMS construction method uses a high-performance resin binder with outstandingly high durability and swift hardening and a special small grain size aggregate.

Features

- Road surface strengthening can be planned, and aggregate scattering due to twisting at intersections and the use of tire chains in cold regions can be inhibited.

- Maintains the low noise function.

- Skid resistance will be improved.

- Clogging can be inhibited.

Applications

- Intersections and vehicle stopping areas

- Porous asphalt paving subject to severe usage conditions such as curves and bus lanes

- Expressway interchange approach roads, service areas and parking areas

- Car parks

- Porous asphalt paving in cold regions

PRMS Multi-Functional Method

※For anti-freeze function, PRMS Multi-functional method which rubber crumb is used as main material is prepared.